Material and Construction

Our batch reactors are constructed of strong and durable materials used for high temperature and chemically active environment. These possibilities are:

Stainless steel

Provides an excellent solution in aggressive surroundings while offering easier maintenance.

Carbon Steel

The most cost-efficient option when the chemical environment isn’t extremely aggressive.

Glass-lined Reactors

The perfect solution for very destructive or corrosive actions thanks to both the glass and metal features.

All our reactors are designed to cope with high pressure and temperatures allowing their application in diverse industrial settings. Our reactors come in different sizes which are customizable between 100 up to 30000 liters in order to suit your requirements.

Key Features

Customizable Sizes

Suitable sizes are between 100 to 30000 liters to ensure the reactors fit correctly to the tasks at hand.

Temperature Control

There are systems for temperature control to serve for the purpose of controlled reactions.

Durable Materials

These may be made from Stainless steel, carbon steel, or glass-lined materials, which are resistant to corrosion.

Safety Measures

Contains safety valves & super pressure control measures to prevent exceeding the safe working conditions.

Easy Maintenance

Minimal downtime since they are easy to clean and maintain.

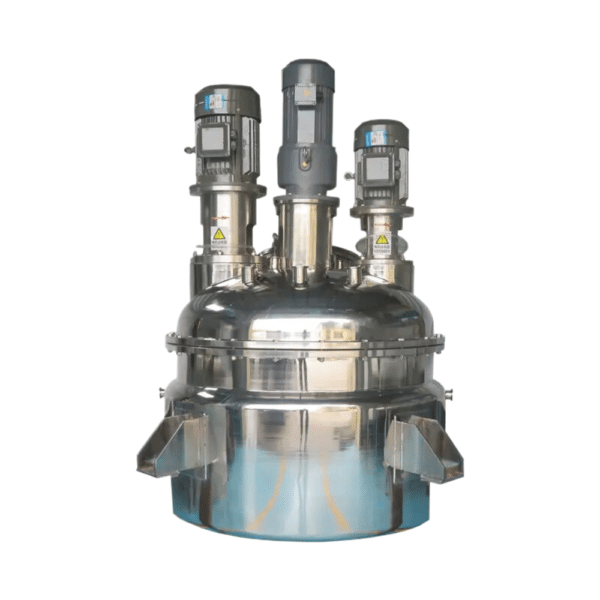

Advanced Mixing Technology

High efficiency mixing systems are included to provide uniform reaction conditions for your processes.

Applications

Used in different sectors in the simplest processes that demand flexibility, batch reactors are a favorite choice for cross-industry applications:

Pharmaceuticals

Best suited for the manufacture of small batch drugs or specialized chemicals.

Chemical Processing

Appropriate for polymer creation, organic chemicals production, among others.

Food and Beverage

Involves using such mixtures for fermentation, flavoring, and producing high-quality products.

Cosmetics

Specifically, for batch mixing of creams, lotions and other cosmetic products.

The batch reactor concept is ideal for companies looking to expand their operations or incorporate varied processes as they are easily modified to fit new processes.

Common Questions

Q1: Is it possible to change the size of the reactor?

Definitely! We provide 100-liter to 30,000-liter reactors to meet most production capacity requirements.

Q2: Which material options does the reactor have?

Depending on the process, our reactors come in stainless steel, carbon steel or even glass lined.

Q3: How is the maintenance of the reactors done?

Our reactors are manufactured such that their cleansing and repair takes very short periods which allow your production activity to go on effectively.

Q4: Are these reactors suitable for high temperature reactions?

Yes! Our reactors are designed for high temperature and high pressure thus facilitating a wide range of reactions.

Advantages of Our Batch Reactors

Customization

We adjust your reactor to your needs as these come in sizes of 100 of liters to 30,000 liters.

Durability

Top grade materials that can withstand corrosion and other forms of damage were used to manufacture these products thus guaranteed long lasting products.

Versatility

Pharmaceutical to food processes, our batch reactors can perform various processes.

Safety

All operations undertaken and conditions experienced are safe due to provided safety features.

Our batch reactors are the best alternative solution for industries that demand reliability, precision and experience. We have a commitment to quality as providing high quality equipment that satisfies modern production processes is crucial.

Contact Us

Would you like to increase your production efficiency with a custom manufactured batch reactor? You may contact us and tell us of your need and we will help you with the most appropriate solution for your requirements.