Key Features of a 100 Gallon Mixing Tank

In case you have decided to go for a 100 gallon mixing tank, it would be prudent to investigate the specific features that you will be able to use. Following are some of the important features which help in effective use of these tanks:

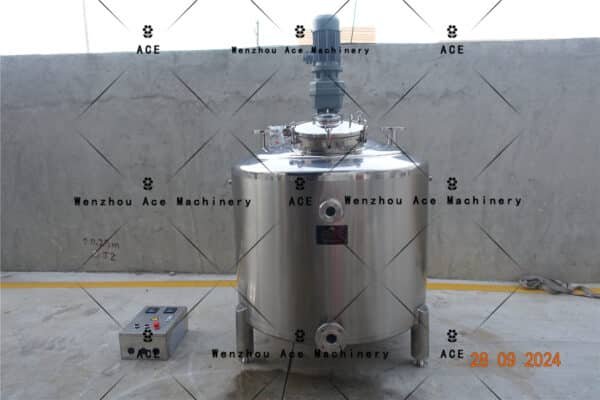

1. Superior Strength

Mixing tanks shall be constructed using materials such as stainless steel or polyethylene, which ensures strength, corrosion resistance, and eventually longevity of use. Stainless steel is popular with those industries that require sanitation and quick clean up after work, such as food, pharmaceutical, and cosmetics industries.

2. Effective Agitator Systems

The performance of a mixing tank mainly hinges on its agitation system. For a mixing tank of a volume of 100 gallons, it is possible to construct the agitator for both high and low viscosity liquids. Whether the liquids are as simple as water or viscous liquid mixtures like syrup and cream, the variable speed agitating paddle with an adjustable rotation speed is able to perform the task of homogeneous mixture with effectiveness and efficiency.

3. Customization Options

Additional features such as heating jackets or insulation and even a temperature mechanism can also be incorporated onto tanks. This makes the 100 gallon tank quite useful for temperature-sensitive industries, as there are various conditions that require mixing of specific components under specific conditions.

4. Mobility and Compact Design

There is a trade-off between the size and mobility. For example, a CMB-100 gallon tank offers such a trade-off, as it gives wallop and mobility. These tanks are big enough for batch production but in the same breath, are small enough to be easily moved on casters or wheels, making them ideal for production processes that are flexible for businesses.

Applications of a 100 Gallon Mixing Tank

The 100 gallon mixing tanks find application in many industrial processes owing to their ease of handling and multipurpose features. Some of their common uses include:

1. Food and Beverage Industry

Used for the production of sauces and containing syrup or dairy products, a 100 gallon mixing tank can make large volumes of products with accurate temperature control and with great ease. It is commonly used in food processing to produce large quantities of consistent quality products.

2. Chemical Manufacturing

Apart from the food and beverage sector, chemical industries also depend on these tanks for the mixing of reagents, solutions, and various chemicals. These materials are strong and resistant to corrosion, thereby reducing the risk of using hazardous, flammable materials.

3. Pharmaceutical and Cosmetic Production

For the pharmaceutical and cosmetic industries with high accuracy and cleanliness standards, specialized agitation tanks are developed which can produce emulsions, suspensions, or creams of various viscosities in a 100 gallon mixing tank.

4. Paint and Coating Industry

The strainers and the additional mix of insoluble particles in these tanks aren’t a costly problem, plus the depth of the tank makes these tanks suitable for mixing base paints with a large volume of additives.

Advantages of a 100 Gallon Mixing Tank

1. Improved Effectiveness

The 100 gallon mixing tank has the capacity which is adequate for commercial usage without compromising on mixing efficiency. This is bound to improve productivity since production cycles will be relatively low.

2. A Viable Market Investment

These tanks are quite economical because they come in the right capacity and can be bought at a reasonable price. A 100 gallon tank, on the other hand, provides room for development without large capital expenditures being required.

3. Universal Applicability

The wide range of available features and characteristics of a 100 gallon mixing tank makes it suitable for various materials and production needs, thus being used by different industries.

4. Low Maintenance

In industries where cleanliness is of utmost importance, parabolic stainless steel models are fairly simple to clean and maintain. Automating the cleaning process by employing clean-in-place (CIP) systems also reduces the amount of downtime required for cleaning between batches.

How to Choose the Right 100 Gallon Mixing Tank

In case you’re looking for the best 100 gallon mixing tank for your garage, below are some important considerations:

1. Material of Construction

Select a construction material that can withstand the harsh chemicals it is meant to mix. Stainless steel is useful for food, beverage, and medicines, while polyethylene could be used in areas that do not experience high levels of stress.

2. Agitator Type

You may require a certain type of agitator depending on your product. For example, paddle or propeller type agitators are usually used to mix low viscous liquids, while higher viscous products such as creams and gels can benefit from turbine or anchor type agitators.

3. Heating and Cooling Capabilities

In cases when the temperature needs to be regulated, verify that the tank has heating or cooling jackets. This is very critical in cosmetic and pharmaceutical processes, which need tight temperature control.

4. Safety Features

If you are supposed to use explosive chemicals, look for tanks with pressure release valves, safety interlocks, and spill containment features.

FAQs About 100 Gallon Mixing Tanks

1. What are the common materials used in a 100 gallon mixing tank?

A 100 gallon mixing tank could potentially be manufactured using a variety of materials. The most common of the 100 gallon mixing tanks is constructed out of polyethylene or stainless steel. Furthermore, a stainless steel feature is most appropriate where there is a need for high levels of hygiene and resistance to corrosion, while a polyethylene feature is suitable for general purposes of making mixes, which may not demand a high level of hygiene.

2. Can a 100 gallon mixing tank handle high-viscosity liquids?

Yes, depending on the type of agitator mounted on the vessel’s interior, a 100 gallon mixing tank can sustain high viscosity gels, creams, pastes, and similar materials.

3. Is a 100 gallon mixing tank suitable for temperature-sensitive products?

Yes, a few 100 gallon tanks have heating and cooling jackets that can be placed around the tank for the control of temperature when mixing the products.

4. How do I maintain a 100 gallon mixing tank?

Cleaning and inspection should be done regularly since they are essential tasks that guarantee the efficiency of target use over the functions of the tank. Strengths of stainless steel tanks help in effective cleaning as well, which can be automated using CIP systems.

5. What industries commonly use 100 gallon mixing tanks?

These types of tanks are utilized in other broad industries, which range from food and beverage, chemical and manufacturing, and also in the cosmetic and pharmaceutical areas.

6. Is it possible to relocate a 100 gallon mixing tank?

Sure, most of the 100 gallon tanks have wheels or casters, which makes them easy to move around the facility.

Who’s looking for a 100 Gallon Mixing Tank?

Businesses seeking to enhance production processing effectiveness in such industries as food, pharmaceutical, or any other that requires steady and dependable mixing will find a 100 gallon mixing tank to be the ideal assist or. Take advantage of this sometimes little part but highly functional addition to boost your production and don’t lose the chance to upgrade your production. Call us now to see all the possibilities that our 100 gallon mixing tanks have to offer and find the right model that fits your business.