Tank Volume and Power Variants

In terms of volume, our double jacketed mixing tanks are available from 50 gallons to 10,000 gallons, making them suitable for both small plants and bulk medium-scale industries. Depending on the tank size, the power ranges from 0.75KW to 55KW, thus satisfying any processing volume or material viscosity requirement.

Voltage specifications need not be a limitation when choosing a suitable mixing tank, as they can be tailored to suit the particular region. This can range from 110V to about 600V with no difficulty. A mixing tank with such specifications can easily be integrated into a production unit, regardless of geographical location.

Heating Options

Our double jacketed mixing tanks offer two main options for heating, catering to the diverse needs of production:

Electric Heating

This method is suited for critical temperature requirements, particularly in cases requiring precise control, such as in the pharmaceutical and food industries. With electric heating, there is consistent and uniform heat throughout the tank.

Steam Heating

Primarily used for bulk or industrial use, steam heating is highly efficient when large volumes of material need to be heated quickly. This method ensures quick and uniform heating, especially for larger tanks.

Both methods maintain consistent heating, reducing the risk of hot spots or poor mixing.

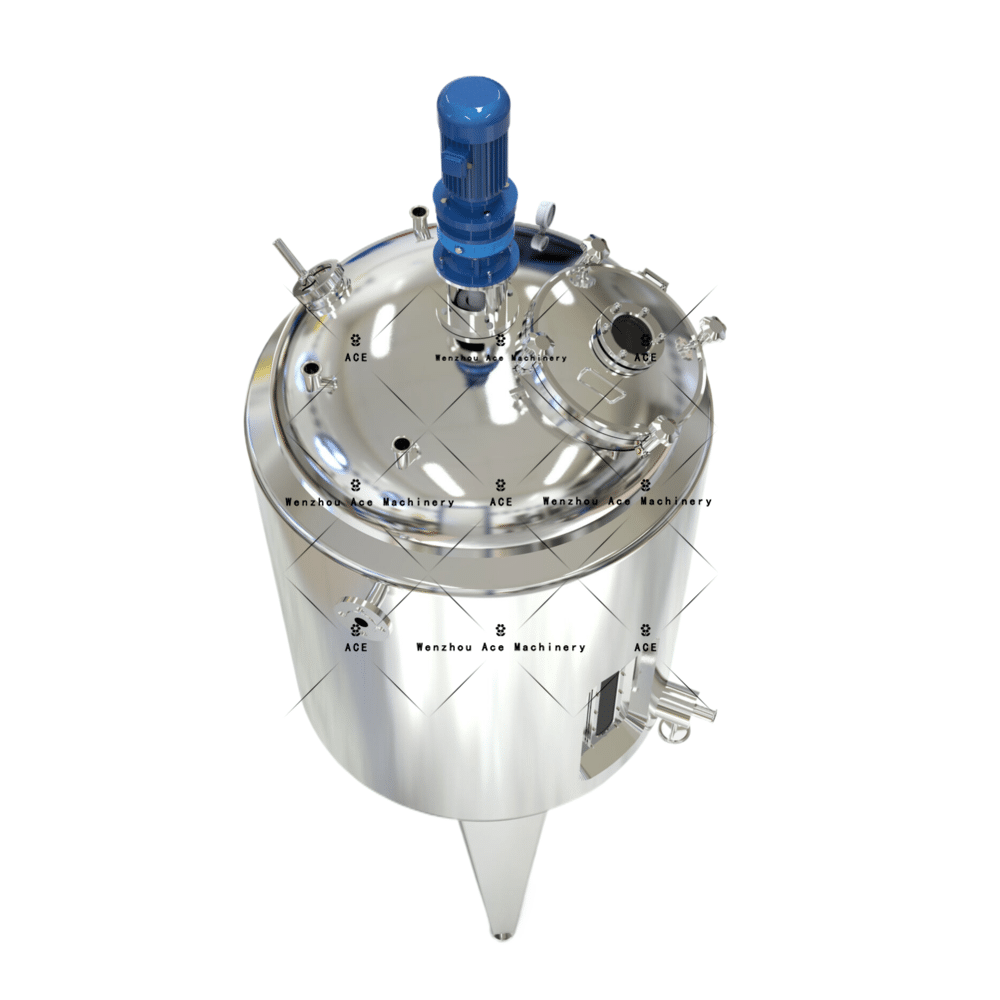

Key Features

Double jacketed mixing tanks offer a range of advanced features to ensure effective performance and high reliability:

Targeted Temperature Control

The double jacket construction ensures even heat distribution throughout the tank, maintaining the optimal temperature for heat-sensitive materials.

Dimensions and Configurations

Our extensive range of tanks caters to both small and large businesses, ensuring they meet the specific needs of each industry.

Choice of Agitators

Depending on the material’s viscosity and requirements, various agitators can be selected to suit the mixing needs.

High-Quality Construction Materials

Made of corrosion-proof stainless steel (SS304/316), our tanks guarantee longer service life and easy cleaning.

Pressure and Vacuum Capabilities

Our tanks can be equipped with vacuum or pressure systems, providing flexibility for specific production processes.

Agitator Options

We offer a range of agitator options to suit varying product needs:

Anchor Agitators

These are ideal for mixing high-viscosity creams, lotions, or pastes.

Propeller Agitators

Best suited for low-viscosity liquids, these agitators ensure minimal air introduction during the mixing process.

High-Shear Mixers

These agitators emulsify and homogenize products, especially in cosmetic or food production lines.

Paddle Agitators

Used for gentle mixing, such as in bio-select yogurt or other delicate products.

Scraper Agitators

These agitators ensure materials do not adhere to the tank walls, facilitating complete mixing with minimal wastage.

Applications

Our double jacketed mixing tanks are widely used in numerous industries, including:

Food and Beverage

Used for making sauces, syrups, dairy products, and liquid formulations, ensuring precise heating or cooling.

Pharmaceuticals

Ideal for preparing creams, ointments, and liquid medicines, where temperature control is essential.

Chemical Production

Applicable for the production of liquids, emulsions, and other formulation mixtures.

Cosmetics

Perfect for mixing lotions, shampoos, and other personal care products, ensuring a uniform and consistent state.

Common Questions

1. What is a double jacketed mixing tank, and what are its uses?

A double jacketed mixing tank maintains an even temperature profile around the inner mixing chamber through the use of a jacket. It is used in processes where maintaining a set temperature during mixing is critical, such as in the food, pharmaceutical, and chemical industries.

2. How does a double jacketed tank improve heating or cooling?

The jacket contains fluid (water, oil, steam) between the tank walls, allowing heat circulation within the product being mixed. This provides consistent heating and minimizes the risk of overheating or texture inconsistency.

3. Can the tank be used for both heating and cooling?

Yes, our tanks are designed for both heating and cooling. Cold water or another coolant can be circulated in the jacket to rapidly cool a product that has been heated.

4. What maintenance is required for a double jacketed mixing tank?

Maintenance primarily involves cleaning, which is critical for the food and pharmaceutical industries. Made of stainless steel, our tanks are easy to clean, and routine checks on the agitator and jacket integrity ensure long-lasting performance.

5. Can the agitator be customized to fit my needs?

Yes, we offer a range of agitators to suit your product’s viscosity and mixing requirements. Whether you need gentle blending or high-shear emulsification, we have a solution for you.

Contact Us Today!

Are you planning to improve your production process by integrating a double jacketed mixing tank? Our skilled team is ready to assist you in identifying a solution that meets your specific needs. Whether you’re looking for a 50-gallon tank for small batch production or a 10,000-gallon tank for industrial operations, we have you covered.

Contact us today for more information, and let us help you enhance the efficiency of your mixing and heating processes.